Heat Treating

Heat treating is any of several methods for altering the atomic structure of a metal or other crystalline structure in order to instill beneficial physical, chemical and mechanical properties, such as strength or ductility. These production and manufacturing techniques utilize systematic heating and chilling to modify the behavioral properties of industrial materials. Bringing a material to extreme high or low temperatures allows engineers to effectively alter its internal microstructure. This in turn changes the physical, chemical and mechanical products of the raw material or finished part.

It is wise to note that heat treating and hot forming are not identical. Hot forming specifically refers to processes that induce visible, plastic deformation of material via heat. Heat treatment, on the other hand, refers to processes that are intended to induce invisible , internal changes at the atomic level. Technically, true heat treatment does not change a material’s overall size or its particular shape. It is true that heat treating and hot forming are closely related and often combined during the same overall process of manufacturing a specific product. For example, heat treatment of an object may soon follow its formation through hot forming. Nevertheless, it is important to keep the distinction between these two related metalworking processes in mind.

Quick links to Heat Treating Information

History of Steel and Heat Treating

Steel accounts for the vast majority of material which undergoes heat treatment. This reality will be further discussed in the following section. Thus, the history of heat treating is invariably intertwined with the history of iron and steel production.

The origin of steel can be traced back to the seventeenth century. Before then, metalworking depended heavily on cast iron, a high carbon iron developed in Chinese and European blast furnaces. In Germany and England, a method known as cementation gradually developed for increasing carbon within molten pig iron. Cementation involved repeatedly heating bars of wrought iron using powdered charcoal and stone boxes. Thus, in a sense, it can be considered one of the earliest forms of true heat treatment. Although steel production was accidentally refined by an English clockmaker named Benjamin Huntsman in the 1740s, production costs remained too high for steel to be widely used for industry. In the mid-nineteenth century, as the Industrial Revolution strained the iron-making industry (e.g. the development of railroads), Henry Bessemer developed an efficient method of reducing the carbon content in molten iron via oxygen introduction. It took approximately a couple decades, however, for this process to be further refined in order to lower steel production costs and spark a steel production boom in the Western world. Around the same time (1860), German engineer Karl Siemens developed an open hearth steel production method with large, shallow furnaces that enabled the production of steel on an even larger scale. By the turn of the century, the open hearth process formed the foundation of steel production.

Today, about two-thirds of steel is produced in basic oxygen furnaces that have replaced the open hearth method. It is estimated that heat treating metal products enhances the overall value of the industry by $15-20 billion yearly.

Heat Treating Process

Typically, metallurgists or other heat treatment professionals determine desired heat treatment operations to achieve the preferred mechanical, chemical and physical properties of customer-specific requests. Naturally, each material which can undergo heat treatment has its own particular microstructure. Small grains or crystallites form a complex lattice, the structure of which is reflected in the characteristics of the raw material and semi-finished products. At risk of oversimplification, heat treating can be conceived of as processes which improve a metal’s characteristics by modifying the size and arrangement of its granular lattice.

Decisions about the specific heat treatment to use in a given scenario typically begin with an analysis of the materials themselves. As alluded to before, iron and steel (defined as iron alloys containing 0.2-2% carbon weight) are, by far, the most common heat treated materials. (Some estimates for the steel percentage of heat treated products range as high as 80%). The differing types and strengths of steel are defined by the particular aspects of the steel’s carbon presence. For example, plain steel refers to steel composed of only iron and carbon, while alloy steels are variations of steel that contain additional elements alongside iron and carbon. Plain carbon steel, free cutting steel, chromium steel, and nickel-chromium steel are further examples of steel types distinguished by differing carbon percentages. Steel is sometimes heat treated in a "raw" form directly out of a mill (e.g. in a bar) or in a form that has also been pre-worked in some other fashion (e.g. cast, forged, stamped, extruded, etc.). While it is the most common heat treating object, steel is far from the only heat treating object. Heat treatment can also be applied to aluminum, titanium, copper, and nickel, among other metals. In addition, while heat treating metals is the most common application other materials such as glasses, ceramics and polymers can also benefit from heat treating processes.

Despite the wide range of different heat treatment processes, each of them can be divided into three basic steps known as heating, soaking, and cooling.

- Heating Stage

- The initial heating of a material is designed to bring it to its critical temperature (the point at which the granular lattice begins to come undone). The exact temperature, rate of heating and duration of heat applications varies depending upon the end goal of the specific heat treatment process. This initial step, including the specified temperature as well as the rate of heating, is critical to the entire heat treating process, since it exerts the most impact on the finished product.

- Soaking Stage

- Once a material has been heated to its predetermined temperature, it must be kept at that temperature for a specified period of time in order to evenly apply the heat treatment. This intermediate step is known as soaking. The specified period of time can range from a few seconds to sixty hours or more.

- Cooling Stage

- Although it involves lowering temperatures rather than raising them, cooling is considered a step in the heat treatment since it is critical to achieving its overall goals. Parallel to actual heating operations, these types of processes also vary . For fast cooling, gas or liquids engulf the material in a process known as quenching. Other processes simply allow the material to cool at room temperature or within the heating furnace. Along with initial heating, cooling (and specifically its rate) exerts a very significant effect on the results of overall heat treatment. If cooling is rapid, the material will have a coarse grain which provides excellent strength and rigidity. Fast cooling on the other hand provides flexibility and ductility by reducing the grain size.

Heat Treating Images, Diagrams and Visual Concepts

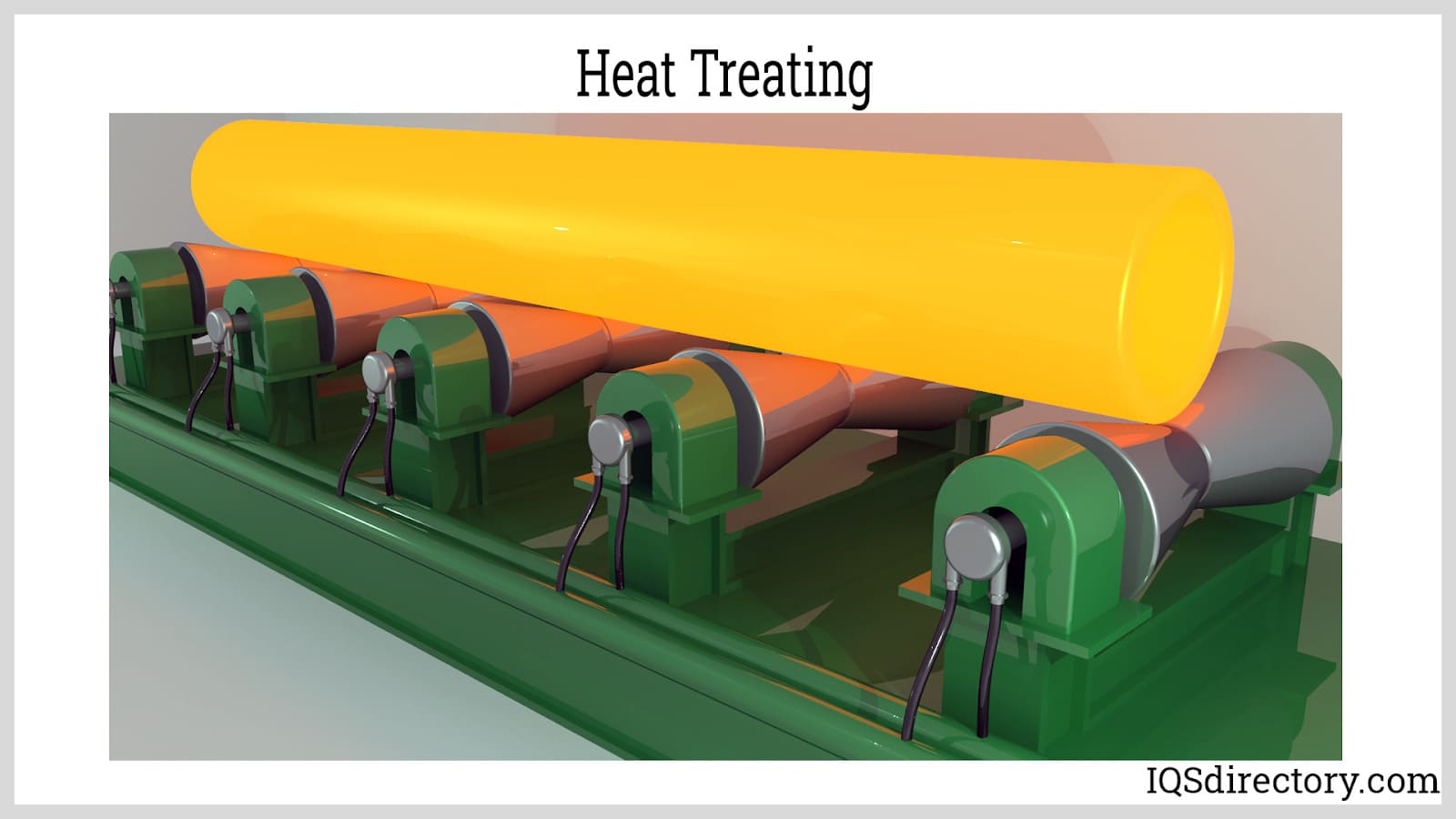

During the stage of heating, the heat must even to prevent distortions or cracks.

During the stage of heating, the heat must even to prevent distortions or cracks.

The soaking stage is used to keep the metal at an appropriate temperature to allow the metal to take the intended structure.

The soaking stage is used to keep the metal at an appropriate temperature to allow the metal to take the intended structure.

The cooling stage allow the metal to be cooled to room temperature, which the rate of colling depends on the type of metal.

The cooling stage allow the metal to be cooled to room temperature, which the rate of colling depends on the type of metal.

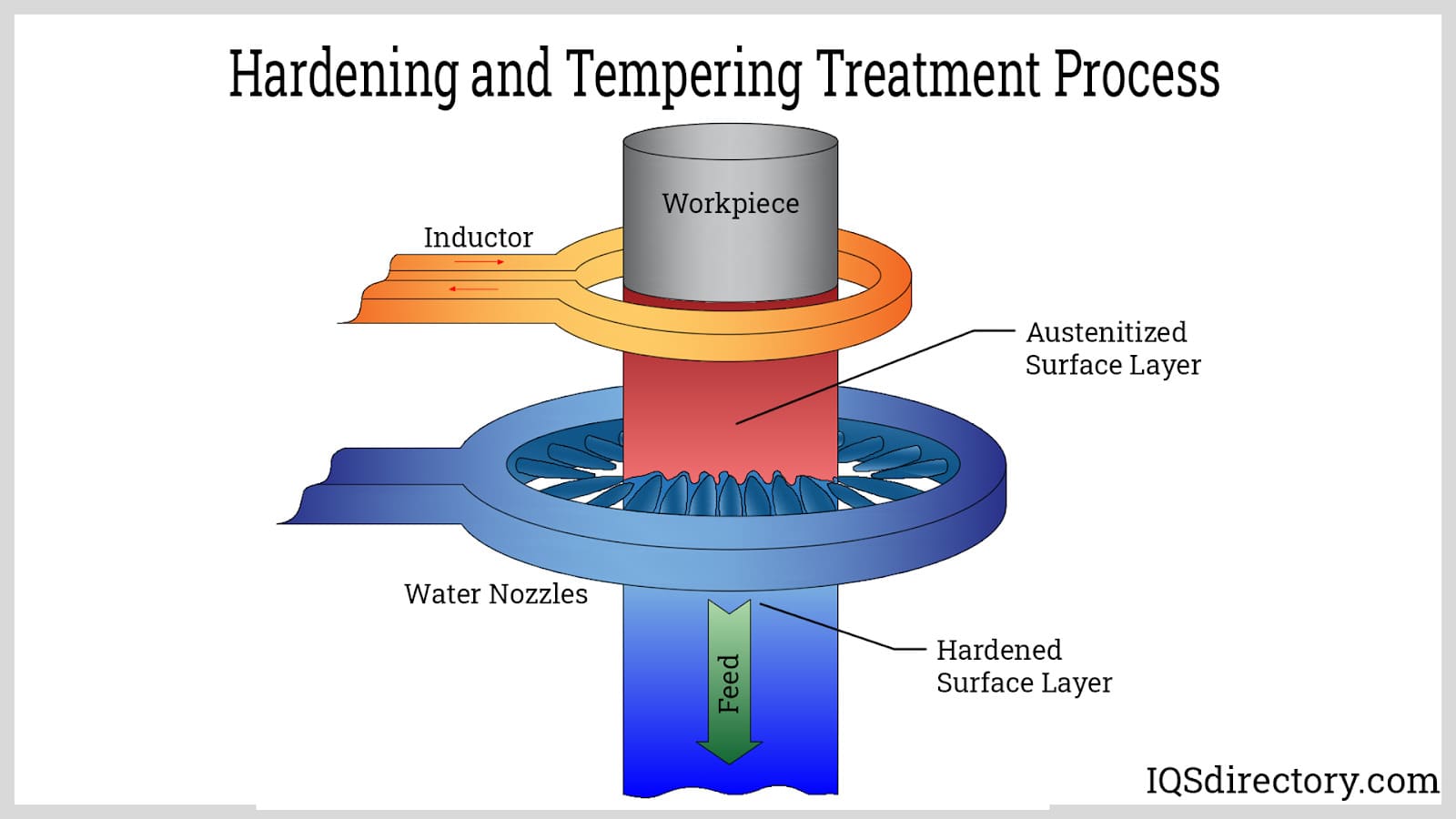

Hardening, a metal working process that occurs in a vacuum, while with tempering the metal is heated to high temperatures to increase its durability.

Hardening, a metal working process that occurs in a vacuum, while with tempering the metal is heated to high temperatures to increase its durability.

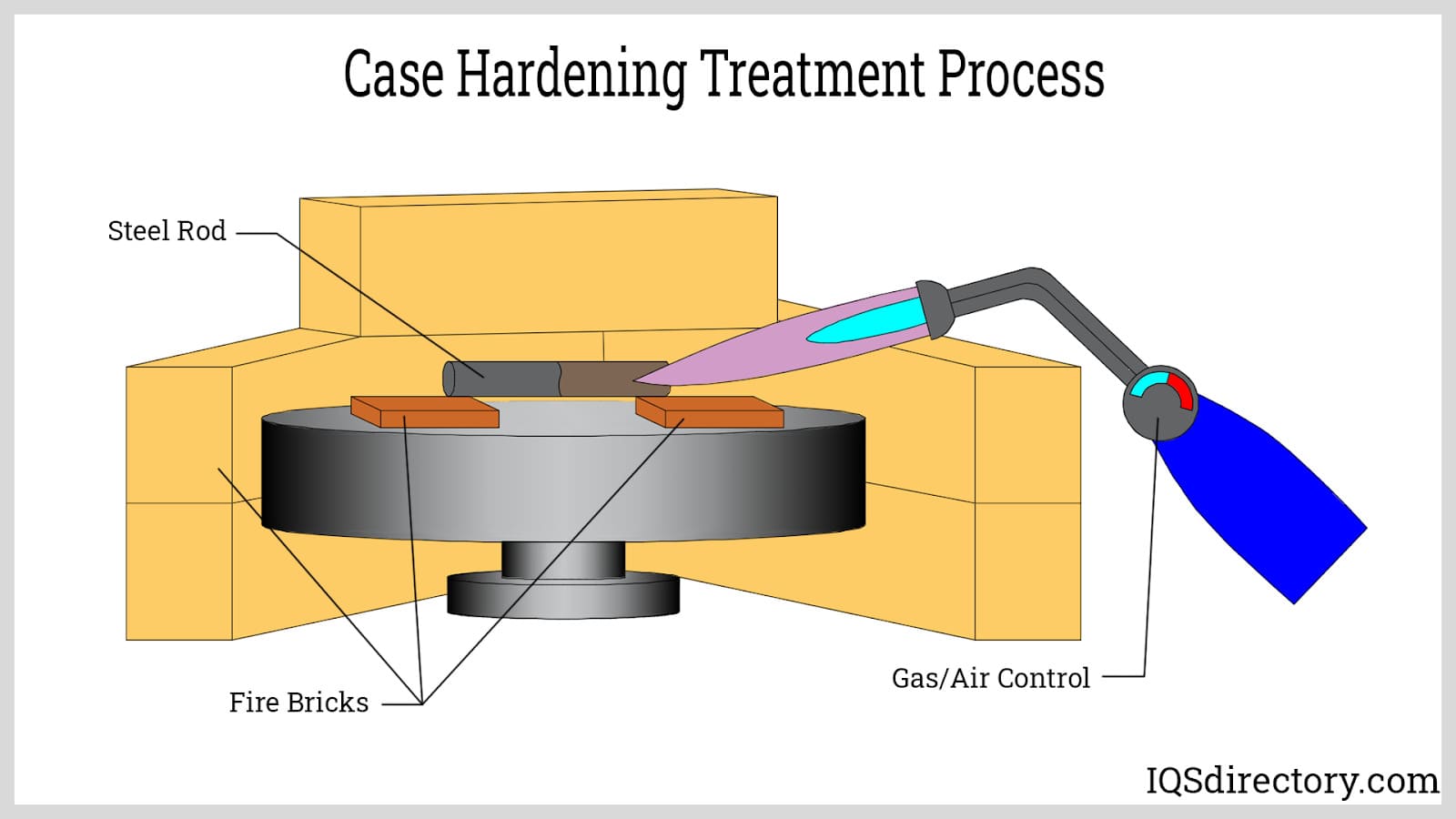

Case Hardening uses high heat with a combination of elements and chemicals to create a hardened outer layer.

Case Hardening uses high heat with a combination of elements and chemicals to create a hardened outer layer.

Cyaniding treating deposits nitrogen and carbon atoms on the surface of the metal increasing the metals strength.

Cyaniding treating deposits nitrogen and carbon atoms on the surface of the metal increasing the metals strength.

Normalizing removes the internal stresses after cold working and restores the structure of the metal.

Normalizing removes the internal stresses after cold working and restores the structure of the metal.

Types of Heat Treating

There are several means of heat treatment, each of which produces a unique effect on a given material. Basic families of heat treatment include annealing, case hardening, normalizing, and tempering. Other types of heat treatment include solution or aging processes and speciality stainless steel processes (S3P).

- Annealing

- One of the most frequently used heat treatments available. This involves subjecting materials to consistently high temperatures above its critical temperature for a predetermined length of time and then slowly cooling them so as to seal in the strength and durability of the material by reducing compositional segregation. (Cooling a part within a furnace at a controlled rate is the slowest method of cooling.) The result of this is more ductile materials as the fine grains allow for bending without brittleness or cracking. Steel often undergoes annealing before being cold-formed.

- Case Hardening

- While many procedures rely most heavily on the physical properties (like annealing), others rely on the chemical properties. For example, case hardening (or surface hardening, since it hardens an exterior surface without altering the interior) requires materials with a high carbon or nitrogen content. The heating and cooling forms a hard exterior shell by drawing the carbon and nitrogen to the surface (more information can be found here). Case hardening has the opposite effect of annealing as it increases rigidity and strength.

- Normalizing Heating

- Can be conceived of as a "pre" heat treatment technique. Since material production or preliminary manufacturing processes (such as forging, welding and cold-rolling) may enact stress on the objects of heat treatment, normalizing often precedes other heat treating techniques. Normalizing involves heating the material or product and then allowing it to cool at room temperature in air. This procedure essentially erases any previous heat treatments.

- Hardening and Quenching

- In a sense, the opposite of annealing. It involves heating material and rapid cooling instead of slow cooling. Hardening refers to the normal heating stage, while quenching refers to rapid cooling via some type of fluid. Water, brine solutions, polymer solutions, and gases are all used for quenching materials at different cooling rates. It is noteworthy that quenching is a type of cooling process which does not alter a material’s microstructure.

- Tempering

- Resembles the opposite of case hardening since its purpose is to diffuse carbon outside of material and allow it to achieve an optimal combination of mechanical properties (e.g. strength, ductility, etc.) To accomplish this, high-carbon material is heated below its critical temperature. Mild and low carbon material does not possess enough carbon for this process to make much of a difference. Cryogenic treatment, or cooling in liquid nitrogen, often precedes heat tempering to relieve stress.

- Precipitation Hardening

- Adds a step to both annealing and hardening/quenching by reheating material at a high temperature after initial heating and quick cooling. This process is also called age hardening and is designed primarily to impart a high degree of uniformity to a material’s microstructure.

- Nitriding and Other Processes

- Further processes (e.g. nitriding) are also used to alter the hardness, tensile strength, yield strength and impact strength of materials in order to produce finished or stock forms ready for use in a broad range of applications.

- Austempering Method

- A method of hardening steel by quenching into a constant temperature medium, such as a salt bath. The resulting product is bainite.

- Brazing Process

- A heat treating process in which melted metallic filler is used to bond two base pieces creating an extremely strong and often hermetic joint.

- Cyaniding Method

- A hardening method that involves carbon and nitrogen absorption on the surface of steel by heating it in contact with cyanide salt and then quenching.

- Flame Hardening

- Used when only a small part of a metal surface needs to be hardened. This method involves heating the surface with an acetylene torch and then quenching.

- Martempering Method

- Used to harden steel by quenching the hot metal in a heat extracting, constant temperature substance, such as salt, and waiting until the temperature is uniform. The metal is then air cooled to form martensite, and tempered as needed.

- Sinter Process

- More commonly called sintering, is a manufacturing technique utilized in a variety of industries to produce solid parts out of powdered materials that are heated to just below the melting point in order to cause particulate adhesion.

- Tempering Process

- The reheating of ferrous metals to increase hardness and reduce brittleness.

- Vacuum Heat Treating

- Involves heat treating within a vacuum furnace for metallurgical reactions and then quenching, usually with gas.

Applications and Products of Heat Treating

A broad range of industries commonly use one or more heat treatment procedures. In fact, within modern industry it is virtually impossible to run a manufacturing operation without using some form of heat treatment. Some of these industries include automotive, hardware, construction, military, tool and die, stamping , trucking, shipping, aerospace, computing and other fields. Various heat treatments are used for a wide variety of products such as cutting tools (e.g. saws, axes), gears, axles, fasteners, fine cutlery, dies, railroad components and even musical instruments.

Heat treatments require a range of specialized tools. Specialized furnaces are, obviously, a critical component in heat treating and come in a wide variety of forms. Some examples include critical furnaces, drop bottom furnaces, car bottom furnaces, elevator furnaces, turn up furnaces, crucible furnaces, and age ovens. Other furnaces allow for induction heat treating as well as vacuum heat treating. These tools, and others such as lasers, torches, heating blankets and salt baths are carefully calibrated to manipulate the composition of heat treated materials and products.

Heat Treating Care and Safety

While heat treatments are very useful, they come with a variety of risks that must be handled with care. Because heat treatments are sophisticated processes which alter the physical strength and molecular stability of a material, it is exceedingly important that calculations and equipment be properly maintained. Inaccurate or failing equipment may lead to improper heating and cooling -- which could cause disastrous effects by producing parts unable to withstand the rigors for which they were designed. Industrial accidents from improperly heated materials are the most serious risk from the lack of careful heat treatment control.

The actual process of applying heat treatments also involves physical safety risks which must be taken into consideration. Operators involved in any heat treating process should wear protective clothing and have fire extinguishers ready in order to avoid scalding or fires. Ultimately, proper equipment maintenance and careful process regulation can ensure that heat treating applications continue to successfully serve many sectors (industrial, commercial and even domestic) with application specific materials that are stronger and more ductile.

Things to Consider When Choosing Heat Treating

When employing heat treated materials in any industry it is important to understand the capacities of heat treated materials which vary depending upon the specific chemical composition of the raw material. For example, aluminum heat treating is vastly different from heat treating steel. Heat treating steel, in turn, may differ significantly from heat treating stainless steel. As a consequence, it is also important to invest in finding a heat shop that possesses a depth of experience, expertise and equipment. Consider factors such as a supplier’s level of investment in state-of-the-art technology and R&D, their track record for consistency, industry-specific accreditation, etc.

Heat treating service shops often become involved at the end of a commercial project. Rather than request a certain procedure, many clients communicate the desired result or requirements of a specific part or piece of material. As aforementioned, metallurgists and other heat treatment professionals then determine the most appropriate heat treatment operations to produce the desired customer outcome. Thus, it is important that you invest in finding a heat treatment provider with a high reputation for customer service.

Heat treating operations themselves must weigh a variety of different factors to determine best business practices. Some of these factors include financial, quality, and environmental concerns. Some scenarios follow below:

- Annealing is one of the most popular heat treating processes. However, quenching may be preferred since it is generally less expensive.

- As an overall industry, heat treating tends to be fragmented and uneven in its distribution of innovation and R&D across its various segments. Although it may be more expensive up front, investing early in up-to-date equipment and R&D aspects of a business may make it more competitive in the long run.

- Although quenching can be accomplished with a wide range of substances, polymer quenching should be chosen over other methods (e.g. oil-based basing) if environmental issues are a top priority.

Heat Treating Terms

- Air Hardening Steel

- A type of steel that does not require quenching to cool and harden, simply air.

- Alloy

- Two or more metals combined for desired properties, such as greater strength, hardness or a different melting point.

- Austenite

- Solid iron and carbon that is created by heating steel above its critical temperature.

- Bainite

- The resulting product when austenite is quenched in a medium at a constant temperature.

- Carburizing

- The process of adding carbon to the surface of steel by heating the metal below its melting point around solids, liquids or gases that contain carbon.

- Critical Temperature

- The temperature at which steel will change its structure to austenite.

- Decarburization

- The loss of carbon at the surface of a metal, due to high temperatures and contact with air, oxygen or hydrogen.

- Hardenability

- The measure of a metal’s ability to harden after quenching.

- Hardness

- A metal’s ability to resist penetration.

- Impact Strength

- A metal’s ability to resist cracking after an impact.

- Martensite

- A type of steel that results from quenching austenite.

- Normalizing

- A prelude to many heat treatments that involves heating a metal above its critical temperature range and then cooling it. This process is done to erase any effects of previous heat treating.

- Oxidation

- A corrosion reaction on a metal that results from exposure to oxygen in the air.

- Pearlite

- A type of steel that is created from the slow air cooling of austenite.

- Quenchant

- The substance that is used to cool a metal in the heat treating process, such as water, oil, brine, liquid salts and air.

- Quenching

- The process of rapidly cooling a red hot metal, with a medium such as water, oil or air, to influence hardness.

- Temper

- A substance’s condition, which in most cases can be adjusted.

- Temper Color

- The color of clean steel at different temperatures, which indicates the level of heat during the tempering process.

- Tensile Strength

- The force at which a metal will break after being stretched.

- Yield Strength

- The point at which a metal will become permanently deformed after stress.